At present, the hot weather in summer has entered, and the uncertainties of production safety have increased. All aluminum processing enterprises must strengthen safety protection, do a good job in heat protection and cooling, and avoid accidents such as fire and explosion.

01 Pay attention to electricity safety

In hot weather, there is a risk of electric shock. When using office and household electrical appliances, it is strictly forbidden to use electricity in violation of regulations, to connect wires indiscriminately, and to use high-power illegal electrical appliances. Especially for old and old electrical equipment, professionals should be asked to test their safety before continuing to use them. All kinds of explosion-proof places shall not use non-explosion-proof equipment in violation of regulations. Electrical workers must operate in strict accordance with the operating specifications.

02 Pay attention to the safety of casting production

(1) into aluminum. The sealed high-temperature molten aluminum is transported from the electrolysis workshop to the melting and casting workshop and poured into the melting furnace. There is a danger of high-temperature molten aluminum gushing out and burning the contractor when the mouth of the bag is opened. It is very easy to cause an explosion and hurt people; if the crane fails to brake or the wire rope breaks during the process, it will cause the ladle to fall off, and a large amount of liquid aluminum will flow out, causing safety accidents such as hurting people and burning equipment and facilities.

(2) Add waste. Recycled aluminum such as waste aluminum ingots and broken aluminum flakes are prone to explosion accidents when they are added to the high-temperature aluminum liquid for secondary melting. The reason is that the waste materials are wet and contain moisture; Liquid splash hurts people.

(3) Casting. The process here is easy to cause the molten aluminum to splash and burn the operator; if the molten aluminum encounters moisture on the way through the casting mold tank, it is very easy to explode; if serious aluminum leakage occurs in the transfer tank, it cannot be disposed of in time, and the leaked aluminum will remain at the bottom of the furnace Or leaked hydraulic oil is prone to fire accidents.

(4) There is also a danger of explosion due to gas leakage.

(5) Put aluminum. The residual aluminum in the degassing box, filter box and launder is discharged into the residual aluminum tank, and the aluminum liquid is very easy to splash out when the aluminum is placed again, and if the residual aluminum tank has not been preheated or has moisture, aluminum will occur. liquid explosion.

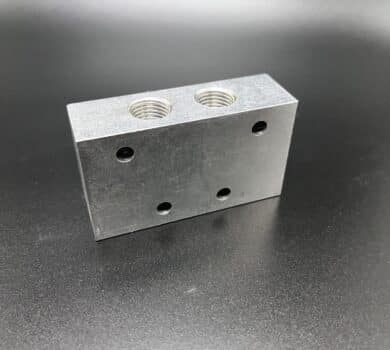

03 Pay attention to mechanical damage

The links that are prone to mechanical damage are maintenance and production processes. Especially in the production of aluminum alloy round ingots and aluminum alloy flat ingots, due to the large number of intermediate products, long production lines, frequent lifting work, and a large number of cross-operations such as cranes, forklifts, and on-site sawing equipment, there are bruises, squeezes, etc. Hidden dangers of safety accidents such as injuries and smashes.

04 Burns, scalds

During the casting process, there are some high-temperature equipment, media or objects that may easily cause personnel burns, such as high-temperature vacuum ladles, smelting furnace doors that are not tightly closed, gas burners that run out of fire when they are ignited, and waste materials that are not sufficiently cooled on site, etc. .

05 Toxic gas

Casting is sometimes refined with chlorine or other poisonous gases. If these gases leak or do not react completely, they will cause great harm to people.

06 Hypoxic environment

In low-lying places, if inert gas leaks and gathers, it is easy to create an oxygen-deficient environment, which will cause the danger of hypoxia to the human body.

07 Metal dust

In some environments where there is a large amount of aluminum alloy dust, high concentrations of aluminum alloy dust may explode when exposed to open flames.

08 Pay attention to heatstroke prevention and cooling

In hot weather, it is necessary to effectively strengthen the ventilation in the workplace to prevent heat stroke. At the same time, factories should actively provide employees with good places to work and rest, do a good job in the supply of drinks to relieve heat, and conduct health checks for workers working at high temperatures. It is necessary to implement the medical first aid measures for heat stroke patients, prepare necessary first aid medicines, and ensure the life, health and safety of employees.